PLANT OPERATIONS

"FABRICATION"

See pictures

of lead pot fabrication from scratch.

Fulton has the capability to

fabricate a wide range of part sizes to proper  dimensional integrity. We fabricate the

mill housings and castings, stress relieve them and route them to a horizontal boring mill

to machine the base, saddle, side plates and bearing surfaces to very close tolerances for

our sugar mills.

dimensional integrity. We fabricate the

mill housings and castings, stress relieve them and route them to a horizontal boring mill

to machine the base, saddle, side plates and bearing surfaces to very close tolerances for

our sugar mills.

All Fulton welders are certified AWSD1.1 and have many years of experience in fabricating

large weldments.

Our welding equipment is state-of-the-art which insures top quality

welds.

Caster Segment being fabricated.

Caster segment ready for welding, stress relieving, and

machining.

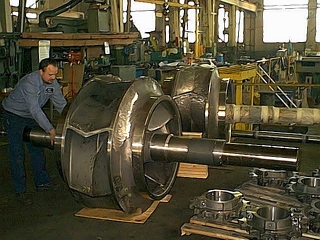

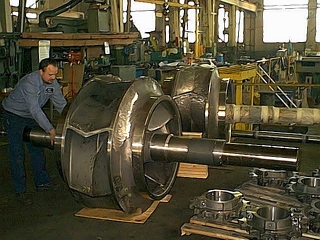

"MACHINING"

Fulton is capable of machining a

wide variety and range of parts to very close dimensional tolerances. we excel at the

manufacturing and machining of a full range of large and small component parts. Our

journeyman machinists have many years of experience in machining very complex parts. Some

examples of our parts machining capabilities are large shafts for industrial rolls, large

pistons and piston rods for the hydraulic pump industry, fans, fan shafts, large  gear sets

and related parts for sugar, steel, and general industry. Fulton's maintenance engineers

can repair and perform routine preventive maintenance on virtually any piece of production

machinery ever built regardless of make or origin. Fulton maintains a 24 hour telephone

line to accept emergency calls for your repairs and machining.

gear sets

and related parts for sugar, steel, and general industry. Fulton's maintenance engineers

can repair and perform routine preventive maintenance on virtually any piece of production

machinery ever built regardless of make or origin. Fulton maintains a 24 hour telephone

line to accept emergency calls for your repairs and machining.

Work stoppages caused by machine failure can usually be prevented by performing regular

preventive maintenance on your equipment during scheduled shutdowns. Call Fulton for

emergency or regular scheduled maintenance repairs and machining.

Fulton can take your rough castings

and machine them to factory specifications. After machining our assembly experts can

finish  the job and send you a turnkey piece of

machinery.

the job and send you a turnkey piece of

machinery.

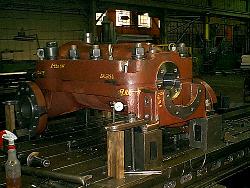

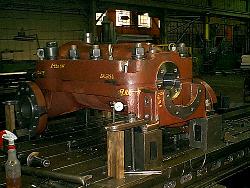

Large 36" pump being align-bored at Fulton Works

"ASSEMBLY"

Fulton's journeymen assemblers

are experts at assembling component parts to exacting customer standards, as well as

disassembling, repairing and re-assembling large presses and other types of equipment with

numerous component parts.

After assembly they completely test the machines and all of the component parts. These

assemblers also oversee erection and installation of Fulton parts at the job site which

insures smooth start-up and minimal problems.

Our 1000 ton hydraulic press at Fulton Works

"

MACHINE REBUILDING"

Completely rebuilding and

upgrading old or worn out equipment and machines so they equal or exceed the performance

specifications of new ones can save manufactures thousands of dollars when compared to the

cost of replacement.

Fulton has rebuilt all kinds of production machinery for manufactures around the world. We

are the worlds leading source for the vital service to the sugar and production industry.

Before you spend money replacing old worn out machinery or equipment, contact Fulton and

let us show you how little it would cost to make your old machinery safe and highly

productive. Machine rebuilding can be a wise decision.

"GEAR BOX REBUILDING"

Complete gear box rebuilding. All work is done in house to guarantee your

job will finished on time and right the first time.

All types of gear reducers

rebuilt:

Worm gear

Herringbone

Spur

Helical

Single reduction

Multi-reduction

High speed

dimensional integrity. We fabricate the

mill housings and castings, stress relieve them and route them to a horizontal boring mill

to machine the base, saddle, side plates and bearing surfaces to very close tolerances for

our sugar mills.

dimensional integrity. We fabricate the

mill housings and castings, stress relieve them and route them to a horizontal boring mill

to machine the base, saddle, side plates and bearing surfaces to very close tolerances for

our sugar mills. gear sets

and related parts for sugar, steel, and general industry. Fulton's maintenance engineers

can repair and perform routine preventive maintenance on virtually any piece of production

machinery ever built regardless of make or origin. Fulton maintains a 24 hour telephone

line to accept emergency calls for your repairs and machining.

gear sets

and related parts for sugar, steel, and general industry. Fulton's maintenance engineers

can repair and perform routine preventive maintenance on virtually any piece of production

machinery ever built regardless of make or origin. Fulton maintains a 24 hour telephone

line to accept emergency calls for your repairs and machining. the job and send you a turnkey piece of

machinery.

the job and send you a turnkey piece of

machinery.