Lead pot job

At Fulton Iron, we do

the jobs no one else will look at. We fabricated 3 lead pots for a customer from

scratch.

The plate came in preformed; we laid it out, cut the transition pieces, fit the

pieces up, finish welded the sections, and stress relieved the unit.

When the weld was completed (1 1/2" full pen weld) the entire pot was

x-rayed, before finish machining.

Plate from forming facility, ready for transition layout.

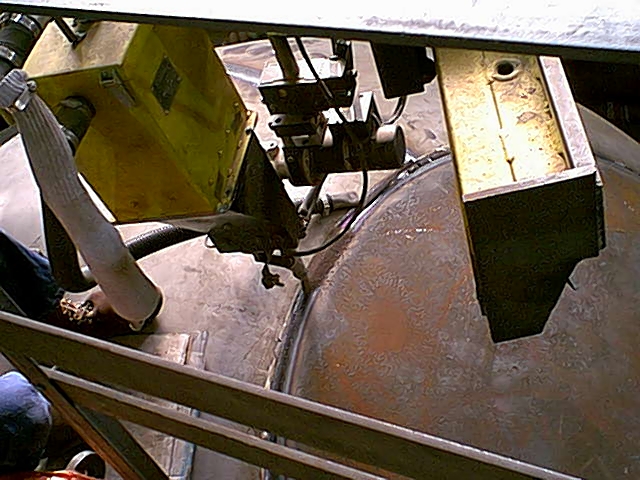

Plate has been fit up and is being welded on our large positioner and sub-arc welding system.

Another picture of the sub-arc process.

Picture of the positioner and the boom mounted sub-arc welder.

Welding completed and ready for x-ray.